What Is Lean Management Principles Explained

Picture this: a master chef in a bustling kitchen. Every movement is precise, every ingredient has a purpose, and nothing goes to waste. The result? A perfect dish delivered quickly to a happy customer. That, in a nutshell, is the spirit of lean management.

It’s more than just a set of tools or a corporate buzzword; it’s a powerful philosophy centered on one simple idea: maximize customer value by relentlessly cutting out the waste. It’s a strategic approach focused on creating more value for customers with fewer resources.

Jump To Section

Earn As You Learn

Earn 25% commission when your network purchase Uplyrn courses or subscribe to our annual membership. It’s the best thing ever. Next to learning,

of course.

What Is Lean Management

Lean management is a systematic way to find and eliminate waste in any process, whether you're building a car or designing software. It’s all about identifying any activity that eats up resources—time, money, materials—but doesn't actually add value from the customer's point of view.

This isn't just about slashing costs. It's a complete cultural shift that puts continuous improvement at the heart of everything you do.

Originating from the world-famous Toyota Production System, this approach is all about boosting efficiency and perfecting processes. The impact can be huge; companies putting lean management principles into practice can see efficiency jump by up to 40% in as little as six months.

The Dual Focus of Lean

At its core, lean thinking boils down to two key objectives that work hand-in-hand to build a hyper-efficient system.

- Define Customer Value: First things first, you have to know what your customer actually cares about. This means stepping into their shoes and identifying the specific features, outcomes, or experiences they are willing to pay for. Everything else is secondary.

- Eliminate Waste: Once you know what "value" looks like, the next step is to put every part of your process under a microscope. You systematically hunt down and remove any step that doesn't directly contribute to that value. This "waste" can be anything from clunky software and long approval times to product defects and redundant paperwork.

This relentless focus on value forces everyone on the team to challenge old habits and ask the tough question: "Does this really help our customer?"

Getting this mindset right is everything. When an organization truly masters these two objectives, it builds a powerful foundation for a culture of continuous improvement. Every single employee becomes empowered to spot and squash inefficiencies, leading to better products, happier customers, and a much healthier bottom line.

The Five Core Principles That Drive Lean Success

Getting your head around the Lean philosophy is one thing, but actually putting it into practice is another story entirely. The good news is that the whole system is built on five core principles that work like a roadmap, guiding you step-by-step. These aren't just abstract ideas; they're actionable stages that take you from figuring out what your customers really want to relentlessly improving how you deliver it.

This process isn't a straight line. It's a continuous loop of refining and improving.

This cycle highlights that Lean isn't a one-time fix. It’s a commitment to constantly striving for perfection. Let's dig into what each of these principles looks like in the real world.

1. Specify Value From The Customer's Perspective

First things first: you have to define value through the eyes of your customer. This is the bedrock of Lean. It boils down to one simple question: "What is the customer actually willing to pay for?" Anything and everything else is just noise.

Practical Example: Imagine a software company that spends months cramming complex new features into its latest update. If it turns out customers only use 20% of those shiny new tools, the other 80% is pure waste—wasted code, wasted time, and wasted money. It doesn't matter how cool a feature seems if nobody actually wants it.

Actionable Insight: Don't assume you know what customers want. Actively seek feedback through surveys, user interviews, and data analysis. Create a "value profile" for your ideal customer that clearly lists the problems they are trying to solve and the outcomes they desire. This profile becomes your North Star for all future decisions.

2. Map The Value Stream

Once you’ve nailed down what "value" means, the next step is to map out every single action it takes to deliver it. This entire journey, from the initial customer request to the final product in their hands, is called the value stream.

The goal here is total, unflinching transparency. You need to lay out the entire workflow so you can see exactly where the waste is hiding in plain sight.

Practical Example: A Coffee Shop

- Order Taking: A customer walks up and places their order.

- Payment: The cashier rings them up and takes the payment.

- Order Relay: The order is passed to the barista.

- Preparation: The barista grinds beans, pulls the espresso shot, and steams the milk.

- Assembly: The drink is put together in the cup.

- Delivery: The finished coffee is handed to a happy customer.

Actionable Insight: Grab a whiteboard and physically map your process with your team. Use sticky notes for each step. For every step, ask: "Does this add value for the customer?" If the answer is no, mark it in red. This simple visual exercise often reveals surprising bottlenecks and wasteful activities that were previously invisible.

3. Create A Smooth Flow

With your value stream mapped and the wasteful steps identified, the third principle is all about making the work flow smoothly, without any interruptions. The mission is to eliminate those bottlenecks, delays, and queues you just uncovered.

Think of it like a river. A healthy river flows continuously. But when rocks and fallen logs (waste) get in the way, they create blockages and slow everything down. Lean is about clearing out those rocks.

Practical Example: For our coffee shop, this could mean moving the milk fridge right next to the espresso machine to eliminate wasted walking time, or investing in a faster payment system to cut down the queue. In an office, it might involve creating a standardized digital folder structure so no one wastes time hunting for documents.

Actionable Insight: Identify the single biggest bottleneck in your value stream map. Focus all your initial energy on fixing that one thing. Often, resolving one major constraint has a ripple effect that smooths out the entire process. Don't try to fix everything at once.

4. Establish A Pull System

Most traditional businesses run on a "push" system. They produce goods based on forecasts and then try to push them onto the market, hoping someone will buy them. This almost always leads to overproduction—the biggest and most costly of all the Lean wastes.

A pull system flips that entire model on its head. Instead of guessing, you only make something when a customer has actually asked for it.

A pull system means nothing is made until there is a clear demand for it. It's the ultimate "just-in-time" approach, minimizing inventory and ensuring resources are only used to create products that will be sold immediately.

Practical Example: The classic example is a restaurant kitchen. The chefs don't just cook steaks all night hoping for orders. They wait for a ticket—a "pull" signal from a customer—before they fire up the grill. This prevents wasted food, cuts down on storage costs, and guarantees every customer gets a fresh meal.

Actionable Insight: Implement a simple visual signal (like a Kanban board) to manage workflow. A task is only "pulled" into the "In Progress" column when a team member has the capacity to work on it. This prevents individuals from being overloaded and makes it clear when there is real demand for the next piece of work.

5. Seek Perfection Through Continuous Improvement

The final principle is arguably the most important because it never ends. Lean isn't a project you complete; it's a culture of Kaizen, which means continuous improvement. It’s about embedding the practice of making small, incremental changes every single day to make things just a little bit better.

Practical Example: A software development team holds a 15-minute "stand-up" meeting every morning. They discuss what they accomplished yesterday, what they'll do today, and—most importantly—any roadblocks they're facing. This simple, daily habit creates a constant feedback loop for identifying and solving small problems before they become big ones.

Actionable Insight: Schedule a regular (weekly or bi-weekly) team retrospective meeting with a simple agenda: "What should we start doing?", "What should we stop doing?", and "What should we continue doing?". This creates a dedicated space for the team to own its processes and commit to small, actionable improvements.

How Adopting Lean Principles Transforms Your Business

Understanding the five lean management principles is one thing, but seeing the real-world results they deliver is what truly gets people excited. Adopting a lean mindset isn't just about making small tweaks here and there; it’s about fundamentally rewiring how your organization operates for success. The benefits ripple out across the entire business, touching everything from your financial reports to your team's morale.

These improvements usually fall into three key areas every leader cares about: financial, operational, and cultural. The best part is that each area feeds into the next, creating a powerful cycle of positive change that just keeps building on itself.

Financial Gains and Profitability

At its heart, lean is a powerful engine for financial health. When you start methodically hunting down and eliminating the eight wastes, you directly slash your operational costs. Think about it: every unnecessary step, every product defect, and every minute of idle time is money walking out the door. Getting rid of them makes profitability soar.

But this isn't just about cutting expenses for the sake of it. It's about being smarter with your resources. When you stop wasting money on activities that add zero value, you suddenly have capital freed up to invest in what really matters—growth, innovation, and your people. For example, Mentor Group achieved 90% cost savings using AI video to create their training materials, showing how fresh approaches can obliterate old costs.

Operational Excellence and Efficiency

Operationally, lean principles bring a huge boost in performance and predictability. By mapping out your value stream and focusing on creating a smooth, uninterrupted flow, you drastically cut down lead times—the total time it takes from a customer's order to the final delivery. This means faster service, quicker product launches, and a serious edge over the competition.

Productivity and quality get a major upgrade, too.

- Enhanced Productivity: When processes are smooth and free of interruptions, teams can get more done in less time without feeling overworked or burned out.

- Superior Quality: Lean’s obsession with error-proofing and fixing problems at the source means defects are caught early. This prevents costly rework down the line and keeps customers happy.

This isn’t some far-off dream, either. The results can be surprisingly fast. Industry surveys often show that companies using lean methods can see a measurable return within just six months, all thanks to quick, hands-on improvements. That speed is a huge motivator for everyone involved.

A Culture of Ownership and Improvement

Maybe the most lasting impact of lean is the change it creates in your company culture. It moves you away from a rigid, top-down structure to one where every single employee is empowered to be a problem-solver. This builds an incredible sense of ownership and engagement.

When the people on the front lines are trusted to spot problems and improve their own work, they become deeply invested in the company's success. That proactive mindset is the soul of continuous improvement.

This cultural shift turns your entire workforce into a collaborative team, all pulling in the same direction toward one shared goal: delivering maximum value to the customer. It builds a resilient, adaptive organization ready to take on whatever comes next. Fostering this environment is a massive leadership opportunity, and you can dive deeper into creating a culture of contagious discipline to help guide your journey.

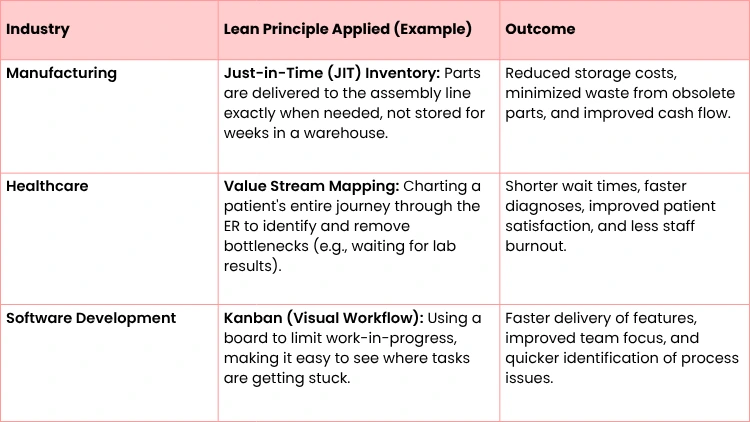

Seeing Lean Management Principles in Action

Theory is one thing, but seeing lean management in the real world is where the lightbulb really goes on. These aren't just rigid ideas for a factory floor; they're flexible strategies that unlock efficiency everywhere. From a busy hospital ER to a fast-moving software team, the core concepts of maximizing value and crushing waste are universal.

Let's look at how three totally different organizations put lean thinking to work and achieve some pretty amazing results.

Healthcare: Streamlining Patient Care

Hospitals are incredibly complex. Every minute counts, and any delay or inefficiency can have serious, real-world consequences. A classic problem is the painfully long wait times in the emergency room, often bogged down by administrative hurdles, duplicate paperwork, and disjointed communication. This is a perfect scenario for a lean intervention.

A hospital embracing lean would start by mapping out the entire patient journey—what we call the value stream. They'd trace every step from the moment a patient walks in the door until they're discharged. This process immediately shines a spotlight on the hidden sources of waste.

- Excessive Paperwork: Think of all the redundant forms patients are asked to fill out for different departments.

- Waiting: This is a big one. Patients waiting for lab results, for a bed, or for a specialist to become available.

- Unnecessary Movement: A nurse having to walk halfway across the unit just to grab supplies from a disorganized storeroom.

By tackling these head-on—digitizing forms, setting up clear communication protocols, and organizing supply closets with a simple visual system (like 5S)—a hospital can slash wait times, boost the quality of care, and bring down costs. The results speak for themselves. One study found that 53% of public hospitals in the U.S. have adopted lean methods, leading to better service and cost control. You can dive into the full findings on lean adoption in hospitals to see the data for yourself.

Software Development: Delivering Value Faster

In the tech world, development teams are constantly juggling feature requests, bug fixes, and critical updates. A lean approach, often visualized with a Kanban board, is a game-changer for bringing order to this chaos.

A Kanban board is basically a visual map of the workflow, with columns like "Backlog", "In Progress", and "Done". This creates a "pull system" where a developer only pulls a new task when they actually have the bandwidth for it. It's a simple idea, but it stops team members from getting buried in work and keeps everything flowing smoothly.

This visual method helps teams ship features faster and with higher quality because it makes bottlenecks impossible to ignore. If tasks are piling up in the "Testing" column, everyone on the team knows exactly where to focus their energy to get things moving again. Of course, leading this kind of shift requires a good handle on making change happen within a team culture.

Fast-Food: Perfecting Standardization

Ever wonder how your favorite fast-food chain delivers the exact same burger and fries, with incredible speed, no matter which location you visit? You're looking at a masterclass in lean principles.

These chains have obsessed over their value stream for every single item on the menu. They’ve standardized every tiny step, from how pickles are stored to the precise sequence of building a sandwich.

This fanatical devotion to standardization kills variation and waste. Employees are trained on a specific, optimized workflow that minimizes extra movement and removes guesswork. The result is a reliable, high-quality product delivered in the shortest time possible, proving how lean can create an amazing customer experience at a massive scale.

Lean Application Across Industries

It's fascinating to see how the same core lean idea can be adapted to fit completely different environments. While the tools might change, the goal of eliminating waste to deliver value remains constant.

Whether you're building a car, treating a patient, or writing code, the lean mindset of continuous improvement and respect for people's time and effort is a powerful driver of success.

How to Begin Implementing Lean Principles

Knowing the principles of lean management is one thing. Actually putting them into practice? That’s a whole different ball game. It requires a clear, practical roadmap. The goal isn't a massive, disruptive overhaul overnight but a series of deliberate, well-planned steps that build momentum.

Think of this as your playbook for turning philosophy into tangible action.

Starting this journey is about getting the right people on board, picking the right battle to start with, and giving your teams the tools they need to succeed. You’re building a foundation for a culture of continuous improvement, one step at a time.

Secure Leadership Buy-In and Form a Team

Before any real change can happen, you need genuine support from the top. And we don’t mean a simple email announcement. Leaders have to actively champion the initiative, allocate resources, and communicate why it matters. Their commitment sends a powerful signal to the entire organization that this is a priority.

Actionable Insight: Don't just ask for approval; ask for active participation. Request that a senior leader serves as the official "sponsor" for your first pilot project. Their involvement will remove roadblocks and demonstrate the importance of the initiative to everyone else. Once you have that backing, assemble a cross-functional team to steer the ship.

Start Small with a Pilot Project

Trying to go lean across the entire organization all at once is a classic recipe for failure. Instead, zero in on a single, specific process. It should be one that’s well-understood but has obvious room for improvement. A great first step here is to create a process map to visualize your workflow to see exactly where the inefficiencies and waste are hiding.

A successful pilot project is your most powerful tool for building momentum. It serves as a tangible case study, demonstrating quick wins and proving that lean principles deliver real results.

Actionable Insight: Choose a pilot project with a clear and measurable outcome. Instead of a vague goal like "improve marketing", pick something specific like "reduce the time to publish a blog post from 10 days to 5 days". This makes success easy to define and celebrate.

Empower Your Team with Training and Tools

Your people are the heart and soul of any lean transformation. It’s essential to give them practical, hands-on training on the core concepts. This isn't about memorizing jargon; it's about giving them the skills to spot and eliminate waste in their day-to-day work.

Introduce a few simple but powerful visual tools to make progress visible and keep everyone aligned.

- Kanban Boards: Use physical or digital Kanban boards. They’re fantastic for visualizing workflow, managing tasks, and immediately spotting bottlenecks.

- A3 Reports: Implement one-page A3 reports for structured problem-solving. This encourages teams to document issues, root causes, and solutions concisely.

Actionable Insight: Don't just train; coach. After an initial workshop, spend time with the team as they apply the concepts. Help them facilitate their first value stream mapping session or set up their first Kanban board. Hands-on guidance is far more effective than a one-off presentation.

Establish Feedback Loops for Continuous Improvement

Finally, remember that implementation is not a one-and-done event. To make lean stick, you have to build in mechanisms for ongoing feedback and improvement. Regular team huddles, review meetings, and open communication channels are non-negotiable.

Actionable Insight: Start every team meeting by reviewing the key metrics from your pilot project. Put a simple chart on the wall showing progress. This constant, visual reinforcement keeps the team focused on the goal and creates a natural opportunity to discuss what's working and what's not. This practice makes continuous improvement a habit, not an afterthought.

Common Questions About Lean Management Principles

As teams start digging into lean management, a few common questions and myths always seem to surface. Tackling these head-on is the best way to get everyone on the same page and build the shared understanding you need for the journey ahead. Let's clear up a few of the most frequent ones.

Is Lean the Same as Six Sigma?

Nope, but they work brilliantly together. Think of it like this: Lean is all about speed and efficiency, its sole focus is to cut out anything that doesn't add value—the waste. Six Sigma, on the other hand, is obsessed with quality and consistency. It aims to make a process nearly perfect by stamping out defects and variation.

That’s why so many companies combine them into "Lean Six Sigma". You get the best of both worlds: processes that are both incredibly fast and incredibly reliable. It’s a powerful one-two punch for operational excellence.

What Is the Biggest Challenge of Implementation?

Hands down, the single biggest hurdle is almost always the people problem: cultural resistance. Lean isn't just a new toolkit you hand out on a Monday morning. It's a fundamental shift in mindset that often goes against years of ingrained habits and "the way we've always done it".

Getting past that inertia requires real leadership, constant communication about why the change is happening, and celebrating those small, early wins to build momentum. Once people see for themselves that the new way works better, they'll start to get on board.

The cultural shift is the real work. The tools are easy to learn, but changing mindsets is where the true transformation happens.

How Does Technology Help Modern Lean Management?

Technology is a massive amplifier for lean principles. Data analytics, for instance, can instantly shine a light on bottlenecks that used to take weeks to find. Digital tools like Kanban boards make work visible to the entire team, no matter where they are, and automation can take over the dull, repetitive tasks. This frees up your people to focus on what they do best: solving complex problems.

Of course, you can't improve what you don't measure. It's also critical to track your progress with the right metrics. You can learn more about how to do that by exploring different key performance indicators.

The key is that technology doesn’t replace lean thinking. It just makes achieving your lean goals faster, more effective, and a whole lot easier to scale.

Ready to build a culture of continuous improvement in your organization? At Uplyrn, we provide the courses and expert guidance you need to master lean management and other critical business skills. Explore our platform today and start your journey toward operational excellence.

Leave your thoughts here...

All Comments

Reply